1923

AN ICON IS BORN

With the introduction of the now iconic RIDGID® pipe wrench, which is still in use today, Ridge Tool Company is incorporated in Elyria, Ohio, USA. Company founder Carl Ingwer, Sr. takes the reigns as president.

1930

DEMANDING MORE

Ridge Tool Company reinvests its profits into new product development, conceiving and testing hand tools with the user in mind. The resulting innovations are known as "Pretested Work-Saver Tools" for their forward-thinking design.

1943

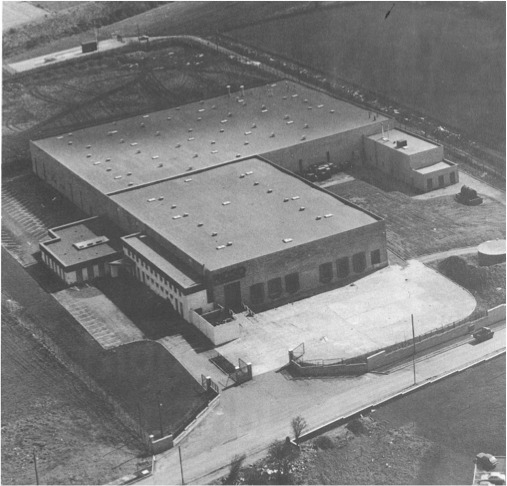

LAYING THE FOUNDATION

The Ridge Tool Company moves to its current World HQ location in Elyria, Ohio USA — home to corporate offices, manufacturing, training facility, and Factory Service Center.

1946

GOING GLOBAL

With World War II coming to an end, Ridge Tool Company begins exporting products that will help trade professionals rebuild the infrastructure across Europe.

1948

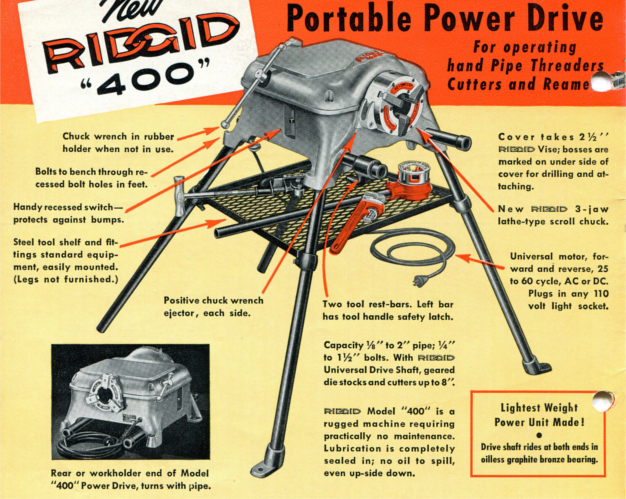

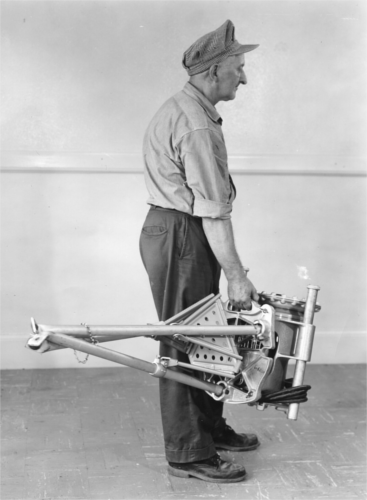

ADDING POWER TO PIPE THREADING: MODEL 400

Hand threading was a slow, tedious process — until Ridge Tool Company developed a better solution: an electric portable power drive that turned the material while hand-held tools cut, reamed and threaded the pipe. Known as the RIDGID 400 Power Drive, the tool was an instant success.

1950

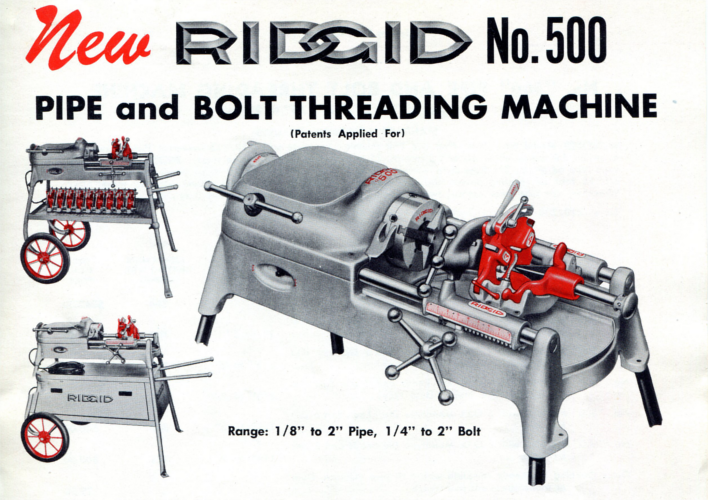

BRINGING MORE VERSATILITY TO PIPE THREADING: MODEL 500

The Model 500 Threading Machine took the innovative thinking behind the Model 400 a step further. The machine cut, reamed and threaded pipe all in one unit.

1957

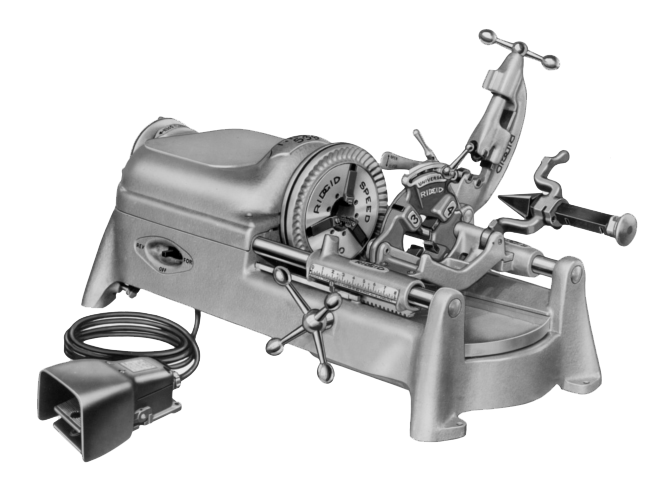

THE DRIVE TOWARDS INNOVATION: MODEL 535

While RIDGID 400 and 500 threaders dominated the industry, Ridge Tool Company continued to look for ways to improve performance. The result was the patented RIDGID Speedchuck (Speed Chuck), which provided a solid grip on material with a simple hand movement. The innovation helped the Model 535 Pipe and Bolt Threading Machine remain the industry standard for over 40 years.

1959

MAKING PIPE THREADING MORE PORTABLE: MODEL 300

The RIDGID 300 not only took the work out of threading, reaming and cutting operations — it also provided a lightweight and portable solution that could be mounted on a truck or stand.

1966

RIDGE TOOL COMPANY BECOMES PART OF EMERSON ELECTRIC

The move partners Ridge Tool Company with one of the most successful companies in the world, allowing the RIDGID brand to increase investment in R&D and expand into new markets.

1967

THE COMPANY ACQUIRES KOLLMAN COMPANY OF ERIE, PA, KNOWN FOR THEIR DRAIN CLEANING PRODUCTS

The company becomes the first choice for professional drain cleaners with the launch of RIDGID/Kollmann drain cleaning machines.

1969

LIGHTENING THE PRO'S LOAD

The company manufactures its first aluminum handle wrench, giving pros a more lightweight option that's ideal for use in overhead or tight quarters. At almost 50% lighter than comparable pipe wrenches, the product still exceeds government strength specifications and carries the same guarantee as RIDGID Heavy Duty pipe wrenches.

1974

THE COMPANY ACQUIRES URICK FOUNDRY OF ERIE, PA, KNOWN FOR THEIR DUCTILE IRON SOLUTIONS

Foundry ownership enables the company to fully control product quality, improve efficiencies and improve agility.

1997

RIDGID.COM LAUNCHES

The company becomes an early adapter of online technology, launching www.RIDGID.com. Today the site is not only a source for product news and information, but also allows professionals to connect and network 24/7.

1998

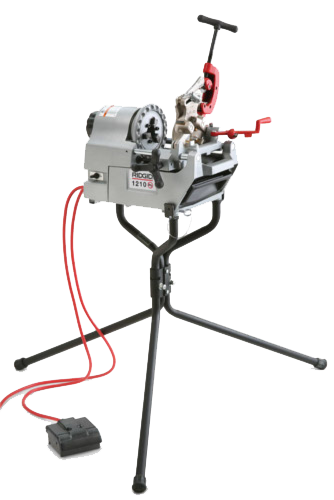

A BETTER WAY TO CUT: THE MODEL 1210

The threading machine offers an unbeatable combination of portability and clean operation. It is the first machine of its kind to cut threads without using oil — making the process more environmentally friendly.

1998

CLEANING UP THE JOBSITE: INTRODUCING WET/DRY VACS

From dirty construction sites and factories to residential workshops and vehicles, RIDGID becomes the #1 choice for wet/dry vacuums in North America.

1999

RIDGID INTRODUCES ITS FIRST PRESS TOOL, THE CT-400

RIDGID Pressing Technology revolutionized the way copper, stainless steel, PEX and multi-layer tubing connections are joined. Today, RIDGID is the #1 name in pressing around the world.

2007

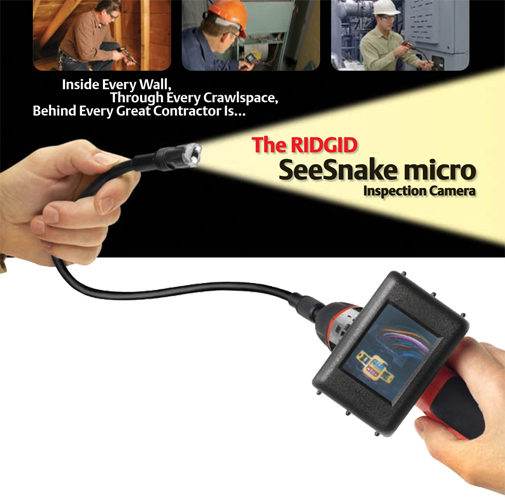

HIGH-TECH PIPE INSPECTION FOR THE EVERYONE

With the launch of the SeeSnake® microReel, RIDGID helps residential plumbers access high-tech inspection capabilities. The video system's small size, economical price tag, superior maneuverability and RIDGID performance make it instantly popular among pros.

2008

A SMARTER WAY TO CUT CAST IRON SOIL PIPE: PRESS SNAP™

The first press tool-powered soil pipe cutter in the world, the Press Snap™ expands the capabilities of RIDGID standard press tools by providing a fast and easy way to cut cast iron soil pipe.

2008

BEYOND THE TOOLS: HELPING PROFESSIONALS GROW THEIR BUSINESS

The company launches RIDGIDConnect™ — a web-based resource that helps professionals streamline their paperwork and customer data so they can more efficiently and effectively communicate with customers.

2010

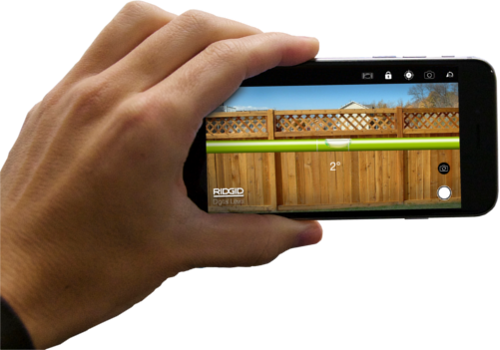

RIDGID DEVELOPS PROPRIETARY SOFTWARE FOR PROS

Recognizing the growth in technology usage among its customers, the company launches RIDGID Software Solutions to create unique and dynamic applications designed to help trades people do their jobs more efficiently. The software development studio eventually grows to support all of Emerson's business units, creating apps not only for RIDGID products, but also for other companies, including ClosetMaid and Liebert.

2012

JOINING IRON PIPE GETS EASIER: MEGAPRESS®

The first iron pipe pressing system in the world allows pros to use a press tool to join iron pipe versus traditional threading methods.

2014

ELECTRICAL TOOL PROGRAM LAUNCHES WITH RE 6

The incredibly innovative and versatile tool allows electricians to cut wire, crimp lugs and punch boxes with one tool.

2015

FAST AND ACCURATE BEVELLING

The RIDGID B-500 Transportable Pipe Beveller allows users to set-up and bevel 12" diameter schedule 40 pipe in one pass in under 2 minutes – faster and more accurately than traditional methods.

2017

WIFI ENABLES FASTER SHARING AND QUICKER APPROVAL

Our first digital recording monitors to include Wi-Fi and Bluetooth connectivity enable customers the added ability to stream and/or record inspections to the latest iOS or Android devices.

2019

Wall-to-Wall Clean

RIDGID® revolutionized the drain cleaning game with the introduction of FlexShaft® technology. These one-stop drain cleaning machines deliver wall-to-wall clean fast on residential and commercial lines up to 125'.

2022

Trenchless Repairs. Faster Results.

Pipe Patching Starter Systems and Kits changed the way professionals can repair 2" to 6" pipe up to 6'. Now, professionals can clean, inspect, and patch all with the brand they’ve trusted for years.

2022

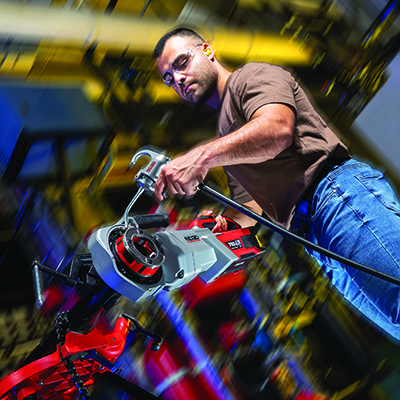

All Power. No Cord

The 760 FXP™ Power Drive delivers precise threads with the FXP battery – taking on-the-go power to a whole new level. New end-of-thread indicator technology improves precision and safety on the job.